|

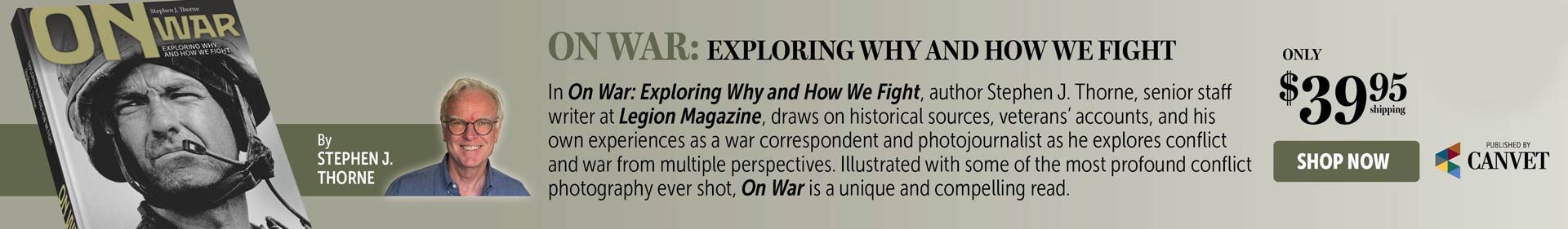

| The twisted remains of the 1907 Quebec Bridge collapse. |

Spanning the St. Lawrence River near Quebec City, the massive Quebec Bridge has a history of triumph and tragedy. Completed in 1917 at a cost of more than $22 million, it is the longest cantilever bridge in the world, stretching more than 1,800 feet between its main piers. For years, the bridge has been viewed as an engineering marvel, but few people know the full story behind its construction and the two disasters that claimed the lives of 89 workers.

The story of the bridge begins in 1887 when a number of entrepreneurs from Quebec City decided there was a need to increase business traffic in the area. The businessmen formed the Quebec Bridge Company and obtained a charter of incorporation to erect a bridge over the river, a few miles upstream from the historic city near the mouth of the Chaudiere River. Due to lack of funds, no work took place until 1900 when the company received financial assistance from the federal, provincial and municipal governments. The Quebec Bridge Company then let a contract to the Phoenix Bridge Company of Phoenixville, Pa., to build the structure.

In 1903, the Government of Canada vigorously promoted the bridge project because it wanted to see the establishment of the National Transcontinental Railway from Moncton to Winnipeg. As part of its commitment to the bridge project, the government guaranteed a bond issue to help pay for the work.

The Phoenix Bridge Company’s design called for a cantilever bridge of 150 feet in height above the high water mark. It was also decided that the structure would have a cantilever attached to piers on each side of the river by anchor arms of 500 feet each and linked together by a centre span initially projected at 1,600 feet. Besides being a transportation link for trains, the bridge would serve as a crossing point for vehicles and pedestrians.

The Quebec Bridge Company selected Theodore Cooper, a well-known American bridge designer, as the project’s consulting engineer. The choice seemed ideal because when it came to professional construction designers, Cooper had few equals on the continent. He endorsed the Phoenix design as the “best and the cheapest” of those submitted, although he decided to lengthen the centre span from 1,600 to 1,800 feet.

Before the parts for the bridge’s superstructure were manufactured, company designing engineer Peter L. Szlapka estimated the weight of the completed work. The Canadian government had hoped to hire its own engineer to review the weight calculations, but Cooper objected and the government reluctantly approved the plans without alteration.

In February 1906, Cooper became concerned when he examined the detailed drawings of the Phoenix Bridge Company and found that the actual weight of the manufactured steel parts far exceeded the weight estimated by Szlapka prior to manufacturing. By then, the south anchor arm, the tower and two panels of the south cantilever arm were ready and six sections of anchor arm were in place. Cooper decided to forge ahead and not introduce any changes. Construction continued because it was thought that the increase in stresses would be safe.

Remarkably, Cooper, who claimed he was not in good health, worked out of his New York City office and did not make visits to the site during the erection of the superstructure. He relied on Edward Hoare, the chief engineer, and Norman McLure, the inspecting engineer for the Quebec Bridge Company, to keep him informed and to consult with him whenever a problem arose.

In June 1907, McLure told Cooper that errors of alignment in some of the lower chord splices on the bridge’s south anchor arm were corrected by jacking them into line. “Make as good work of it as you can,” came Cooper’s reply. “It is not serious. It would be well to draw attention to as much care as possible in future work to get the best results in matching all the members before the full strains are brought upon them.”

In August, McLure telegraphed New York because splices between some of the lower chords in the south anchor arm were bent. Disturbed by this report, Cooper asked for further details on how they became bent. By Aug. 27, the misalignment of one of the lower chords became very noticeable. In just one week, chord 9-L went out of line from three quarters of an inch to two and one quarter inches. But despite these and other irregularities, the Phoenix Bridge Company did not halt construction.

Acting on Hoare’s advice, McLure went to New York City to brief Cooper first hand about the difficulties. After their meeting on the morning of the Aug. 29, 1907, Cooper telegraphed the contracting company in Phoenixville as follows: “Add no more load to the bridge till after due consideration of the facts. McLure will be over at five o’clock.” Cooper believed that the same message would be forwarded from Phoenixville to Quebec City, but this never happened. Further, after talking to McLure, Cooper assumed that work on the bridge had stopped, but this was not the case.

Later that same day, McLure met with Phoenixville Bridge Company officials in Phoenixville and after some discussion it was decided that they would reconvene the following day. However, at 5:37 p.m., Aug. 29, 1907, around the same time that the Phoenixville meeting was ending, the Quebec Bridge suddenly collapsed. In the space of just 15 seconds, the south anchor arm, the cantilever arm and the partially completed suspended span fell some 150 feet into the St. Lawrence River. At least 75 of the 86 workmen on the site were carried to their deaths and property damage was later estimated at over $1.5 million. Only 16 bodies were recovered from the twisted wreckage at the bottom of the river. It was Canada’s worst bridge disaster.

Nearly all the victims were killed by falling debris or drowned. The dead included 33 Mohawk steel workers from the Caughnawaga reserve at Lachine, Que., near Montreal. Most of these men, along with several other workers–about 55 in all–were working on the cantilever arm at the time of the collapse. Ingwall Hall, one of the few survivors, lost two fingers in the accident. He had been standing on a platform known as a “traveller”. Travellers were used to carry heavy loads to specific jobs on the bridge. Hall’s traveller was located at the end of the south cantilever arm.

During the federal inquiry into the disaster, Hall was asked whether he knew something was wrong with the bridge just by the feel and not by the sight of it. “Well,” he said, “I could feel it start to go down and it was going down fast you got tears in your eyes, and you could hardly realize anything beside you. My partner was just about seven or eight feet from me, and I never noticed him and never saw him–never knew anything.”

Hall fell into deep, icy-cold water where he spent a few anxious minutes before being picked up by a makeshift rescue boat.

Elsewhere, about a dozen men who survived the fall were trapped alive in the mangled debris on the foreshore, which at that time of day was relatively dry. For these men and for their rescuers, the situation became more frantic as the tide came in. The rescuers had less than an hour to save the men, and while they tried very hard to get the men out, they lacked the equipment. As the water level rose, the trapped men drowned.

The inquiry, which concluded with a report published in 1908, also heard from the Lajeunesse brothers who were among the few who had landed near the foreshore. Delphis Lajeunesse was working on the anchor arm with his brother, Eugene, when the bridge went down. He recalled the events: “I was on top just putting a turn on the rope to send up a box of bolts when I saw something jerk the bridge. I fell down in my box, stood up, fell down again, and I looked again. I thought the traveller had fallen down on the bridge. The traveller was in the same place. I came to this side of the bridge and I looked, and when I saw the bridge go down in that way I was on that chord, and I thought that chord made the bridge fall.”

Lajeunesse was thrown down on a girder, but managed to get to his feet. At that point he thought he was going to die. “I thought, well, I am finished, but I stood there. Nothing came over on me.” Amazingly, when Lajeunesse landed he was not even dislodged from the girder he was standing on. He also described how he saw his brother emerge from the wreckage, bleeding but not seriously injured.

The Royal Commission, which investigated the cause of the disaster, concluded that “the collapse of the Quebec Bridge resulted from the failure of the lower chords in the anchor arm near the main pier. The failure of these chords was due to their defective design.” The commission attributed this to “errors of judgement” on the part of Peter L. Szlapka, the designing engineer, and Theodore Cooper, the consulting engineer. The commission found that “a grave error was made in assuming the dead load for the calculations at too low a value and not afterwards revising this assumption. This error was of sufficient magnitude to have required the condemnation of the bridge….”

In spite of the enormity of the accident, the federal government decided the project must be completed to establish the rail link for the railway system. So in 1908, the minister of railways and canals appointed a board of engineers that arranged for and supervised the design and erection of a new bridge. Except for the piers, nothing from the previous structure was recoverable. In fact, the wrecked structure was in such poor condition that it was unrecognizable to the men who had been very familiar with it for nearly two years. Much of this debris had to be cleared away before work could start on a new bridge.

In April 1911, the board of engineers awarded a contract to the St. Lawrence Bridge Company of Montreal. As before, the design called for a cantilever-type bridge, but it differed from the previous one with the lower chords of the cantilever arms several times stronger. One important innovation that added strength to the bridge was the K-truss design. This feature was conceived by Phelps Johnson, president and general manager of St. Lawrence Bridge Company.

Construction started in 1913, and eventually the two approach spans, the anchor arms and cantilevers went up on either side of the river. By 1916, the bridge was nearly completed. Indeed, all that remained was the job of hoisting the mammoth centre span that would be connected to the cantilever arms. The 5,100-ton span had been built and was sitting in Sillery Cove, approximately 3 1/2 miles from the bridge site. On the morning of Sept. 11, the workmen faced a difficult task in moving the span upstream, but all went well with that part of the job. The span was carried on scows that were guided by tugs. It was a slow process, but eventually the span was manoeuvred into position between the cantilever arms where huge lifting hangers, attached to the ends of the arms, raised it by hydraulic means off the scows. The span was to be lifted two feet at a time in a repeat operation until it was in place between the two arms. After four successful lifts on the north end and five lifts on the south end, the workmen–about 80 in all–took a break.

At 10:50 a.m, soon after they returned to work, something went terribly wrong. The southwest corner of the span tore away and sagged. A few seconds later, the other ends pulled off their supports and the whole span came loose and disappeared into the river. Thirteen men were carried to their deaths and several others were injured.

A large number of people witnessed the accident from shore and their reaction was one of disbelief. “A cry of anguish went up from the onlookers as the span rushed to its watery bed,” noted an article in one Toronto newspaper. “Women shrieked, men stood dumbfounded, while those directly interested in the building of the bridge could scarcely hold back the tears which welled in their eyes. It was as if they had lost a great friend. They had lived with this span. They had pride in their work and on the day when their desire was to be achieved, fate intervened…. They have lost when victory seemed certain.”

Bridge worker Enoch McCann, who could not swim, was picked out of the chilly water by a rescue boat. “I thought I would never come to the surface again. When I did, I found two pieces of wood wedged in tightly at the elbow joint of both my arms. How they got there I don’t know, but they saved my life.”

Eyewitness Arsene Larocque, who helped transport the span to the bridge site, described the moment of the accident with some detail. “There was a noise like the snapping of steel. The centre span seemed to buckle in the middle and roll over, twisting the great steel girders. Then it disappeared. There was a roaring, grinding sound when it collapsed. The giant arms and the steel bands which held the span shook considerably.”

The investigation by the board of engineers determined that the span did not buckle as Larocque and others claimed. Rather, the loss resulted from the failure of a casting in the erection equipment that temporarily supported the southwest corner of the span.

The Oct. 19, 1916, report by the board of engineers stated that the St. Lawrence Bridge Company “advised your board that they assume entire responsibility for the failure” of the casting in the erection equipment and the “resulting loss of the span.” The report went on to note that the company had taken immediate steps to replace the span. No other part of the bridge was damaged. “One might think in the wake of this second tragedy that the engineers and contractors might have wavered in their determination to proceed with the project, but they did not. On Sept. 20, 1917, the suspended span was lifted into position and fastened to the cantilever arms. At last, the world’s longest cantilever bridge was completed and the first train crossed it in October. Two months later it was opened to regular trains, vehicle and pedestrian traffic.

In 1919, the Prince of Wales officially opened the Quebec Bridge and unveiled plaques in honour of the engineers who had designed and built the magnificent structure. There was no mention, however, of the men who died when the bridge collapsed.

Seventy-eight years later, the Historic Sites and Monuments Board of Canada unveiled a new plaque that commemorates this “remarkable engineering achievement,” but the wording on the plaque pays only scant attention to the workmen who died during its construction.

Editor’s note: The text on the plaque erected by the Historic Sites and Monuments Board of Canada states that 76 lives were lost during the 1907 bridge collapse, other official sources, including the Canadian Encyclopedia, state 75 workmen died in the disaster.

Advertisement