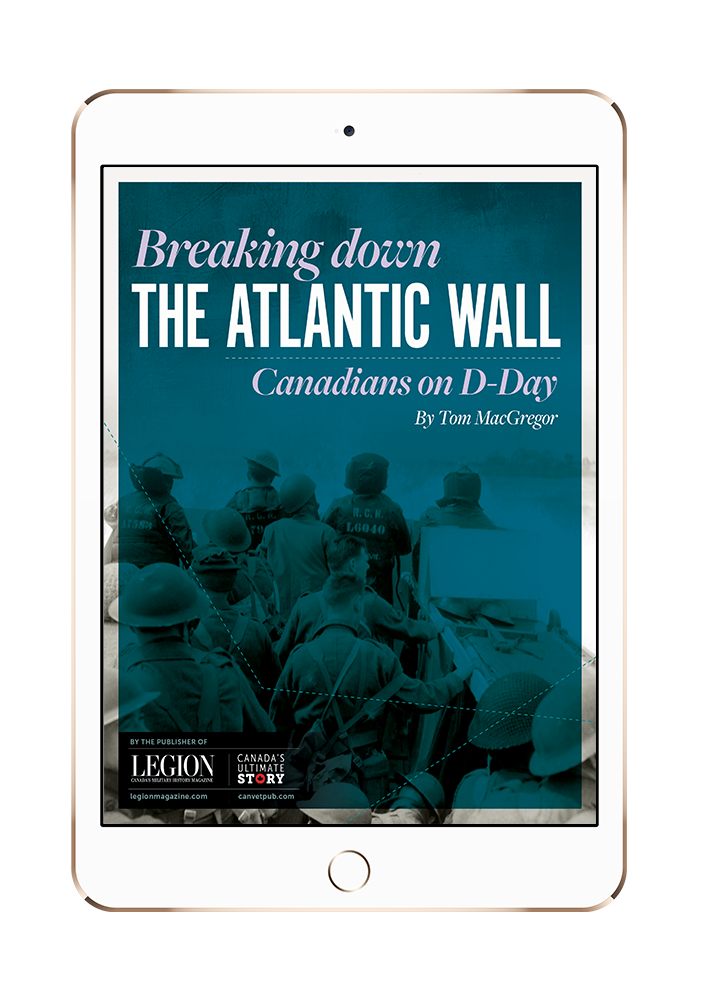

PHOTOS: PARKS CANADA/W. LYNCH 01.10.19(20); PARKS CANADA/W. LYNCH 13.01.03.19(30); HIBERNIA MANAGEMENT AND DEVELOPMENT COMPANY LTD.

An iceberg in Swale Tickle off Newfoundland. Inset left to right: Icebergs along the east coast of Bylot Island; Hibernia crew on a support vessel perform exercises outside St. John’s.

How do you get a menacing 200,000-ton iceberg out of the way? You lasso it. For captains of offshore anchor handling and supply vessels off Newfoundland’s east coast, it’s just part of the job.

On our landing approach, banking low over St. John’s harbour on a clear June afternoon, majestic blue-hued icebergs are a welcome contrast to the rocks of Newfoundland’s eastern shores. But 200 kilometres to the southeast, these beauties aren’t always so welcome. Drifting along the famous Iceberg Alley, the southernmost extent of which was fatal to the Titanic, they sometimes head straight for the exploration rigs and production platforms of Canada’s richest offshore producing oilfields.

That’s when iceberg management teams have to head off what could otherwise be an expensive confrontation. Floating exploration or production platforms can be disconnected and towed to avoid collisions but days or weeks would be lost in the process.

The Hibernia platform, which is set on the sea bottom at 80 metres depth, has been uniquely designed to resist the impact of most icebergs. It’s configured to withstand a collision with a million-tonne berg with no damage. Even a collision with the largest expected–a once-in-10,000-years-size of six million tonnes–would theoretically result in repairable damage. Moreover, with the platform in relatively shallow waters, very large icebergs would likely ground before getting there. But none has ever been put to the test, thanks to the iceberg management teams. “While the platform can withstand the impact of an iceberg we would prefer not to have an iceberg come in contact in the first place because it could cause some damage which would then require repairs. This is why we employ an aggressive ice management strategy that has been very successful,” explains Hibernia spokesperson Margot Bruce-O’Connell.

Towing icebergs out of harm’s way is old hat for Captain Rick Strong. In his St. John’s office overlooking this historic harbour, the Marine Surface Manager for Seabase/Maersk Limited is explaining to me how it’s done. It’s a well-orchestrated process that starts well before an iceberg becomes a threat. “The whole decision on towing it and where to tow it is part of the overall management program once we start getting ice,” he says. “The management component is continuously determining where the ice is at a very early stage.”

Most of the icebergs originate by calving off the ice pack and glaciers of western Greenland and are carried southwards by the cold Labrador Current out of Davis Strait toward the Grand Banks. Sizes vary dramatically: the largest can be the size of the Houston Astrodome football stadium or bigger.

Regardless of size, they all need to be monitored, which is handled by a third party. “A contract goes out to an ice management contractor,” explains Strong. Currently that contractor is Provincial Airlines Environmental Services (PAL). Information on ice movements in the area comes from several sources: the International Ice Patrol–formed the year after the 1912 Titanic disaster–of the United States Coast Guard and the Canadian Ice Service of Environment Canada; satellite and radar technology; airplane reconnaissance, helicopter reconnaissance; ocean current data; wind and wave data; weather and more. PAL enters collected data into a sophisticated trajectory modelling program that can identify those that may be drifting into the danger area. Programs are getting more sophisticated: one currently being developed by the National Research Council of Canada and the Canadian Ice Service hopes to improve predictions by 30 per cent.

When the program forecasts that a particular berg is making a beeline for an offshore asset, its operator is alerted well in advance. That’s when Seabase/ Maersk gets the notification to spring into action. Vessels used for towing serve many functions.

“Anchor handling tug supply (AHTS) vessels are normally deployed,” says Strong. “They have the power and the winches and everything.” Other vessel types on Seabase/Maersk’s roster are also equipped for the job, like the Maersk Placentia tied up not far below Strong’s office window. But the vessels aren’t usually dispatched from port as there’s normally an AHTS doing other duties in the area that can be at the berg within a couple of hours of a call. “Steaming at 10 knots we can be there in two or three hours,” says Strong. This is ample time, as the typical berg drift rate is less than one knot.

The dispatched ship heads out to have a look. If it’s determined to be a threat then it needs to be manipulated–towing or whatever it might be. When a captain gets to the berg, Strong says he sizes it up to determine the best course of action. Shape, size, sea conditions, weather, are all important inputs. “Each situation is unique,” he says.

The determined plan of action is part of the teamwork. “The decision is between yourself and the ice management team,” explains Strong. Most are towed, which means particular factors must be looked at. “If the iceberg is towable–meaning that a rope will stick to it–the biggest issue is its edges. Will the rope stay on it? If it’s a very round iceberg, as soon as you put the power on, the rope will slip off. If it has pieces that a rope can hook up on then it won’t rise up. And then as you bring up power to change the drift angle then the rope will stay put so you can put a force on the berg.”

The rope Strong refers to is an eight-inch diameter poly rope that floats. “Ropes are usually 400 metres in length,” he says. “We have three or four lengths on board. Eight hundred metres of rope will normally keep you well clear of the berg as you go around it.”

Before going around for the ‘lasso’, the rope is attached to a buoy. The vessel then encircles the berg, staying within approximately 200 metres as the rope is played out. When the circling is complete back to the buoy, the halyard is connected to a tow cable and roughly 2,000 metres of cable is played out before the tow begins. “It’s a three-inch diameter cable wire,” explains Strong. “After roping the berg with the floating rope you bring it around and connect it then pull it aboard to connect with the tow line.”

Power is then applied to take up the slack and gradually get the massive ice chunk’s momentum in motion. “We’re not really physically towing it,” says Strong. “We’re applying 70 to 100 tonnes force in a direction perpendicular to the drift, changing the drift angle.” If tackled soon enough, just a small correction is often needed. Strong provides an example: “I was on an iceberg one time 16 miles due north of an offshore asset and it was drifting at about one knot. It looked to be close to a collision course. I put the rope on it and perpendicular to the drift angle and the berg passed seven miles from the asset. So you’re really just changing the drift angle.” Changing that angle early enough in the berg’s course minimizes the amount of tow needed; small changes further out result in wider misses.

Strong explains it as being a ‘parallelogram of velocities’. “If you’ve got a drift of about a knot you may or may not change that (component of) speed,” he says. “What you will do however is change direction so you get a resultant drift rate.”

How does he know when he has applied enough force? “It’s pretty well standard in the industry,” he says. “We run up around 80 tonnes (of towing force) usually. When we get up around 100 tonnes the rope won’t stay on (the iceberg). History has kind of taught us a lesson that (a) 70- to 90-bollard pull seems to be a manageable number.” What he’s referring to here is the measure of the force on a vessel’s bollard, calculated using a load cell–an electronic gauge that measures force on a vessel’s bollard. Seabase/Maersk’s newest vessels are cleared for a 219-tonne force. He adds that if you apply too much and lose the berg you’ll lose probably two hours. “You can set up in about an hour, but by the time you get your speed up you’re actually two hours. If you’re late getting to the berg that time can be critical.”

And how does the captain know when his captive berg is safely off the danger trajectory? “You don’t really,” he says. “What happens is you’re continually reporting your position to the ice management people and they are basically using tactical information on the bergs and they advise when to release it. They’ll either dispatch you back to the asset or to something else. They’ll monitor the one you dropped, but then you might need to go to another one.”

Post-tow monitoring is important. Sometimes there are surprises. Once a berg has been towed to a safe place and released it can unexpectedly change to a new threatening course. “All of a sudden they can come from the south and curl around and come up again, picking up the Gulf Stream,” says Strong. “It can depend on the currents.”

Other surprises captains need to watch for are rollovers. Anticipating these is an acquired sixth sense. “You sort of hear it,” explains Strong. “(Once it starts) it goes really quick but there’s something that changes, something that’s come off to change the weight, to create a rolling moment to turn it. I have seen many roll–when you see it afterwards you don’t recognize the berg. It’s a completely different shape.”

Icebergs can roll while under tow, too, but that’s manageable and not as dangerous as it would seem. “As long as you don’t lose the tow you can continue,” he says. “You’re 2,000 or 3,000 metres away when towing so there’s no real danger to the vessel.” Slack in the tow cable helps reduce the risk “The force is actually being applied in a downward motion on the wire–because of the weight of the wire from the vessel,” explains Strong. “Depending on the force you apply the wire actually creates a catenary under the water so your 70 tonnes force is not directly horizontal; it’s also in a downward motion and that works to your advantage.”

To reduce the chances of a rope slipping off, a newer towing device is often used in place of the rope. “It’s sort of like a drag net or a big fan mesh just below the surface that wraps around, instead of having just one rope,” he explains. “It gives you a greater opportunity to cup things.”

But some icebergs just don’t take to any kind of towing. Strong says these can be the most dangerous ones. He shows me a picture of one that’s untowable: it looks like a gargantuan bald head floating in the waves. Because they can’t be towed, other techniques are used. “On a growler like this one, we use cannon or prop wash,” he says.

The Maersk Placentia has a water cannon that wields immense power. “The force of that water can push a vessel back at three knots,” says Strong. “It’s 3,200 litres per hour–a 20-inch line coming down to a five-inch nozzle. A 2,400 horsepower engine drives it.” It’s a fire cannon and can be used for all sizes of bergs. “It’s a significant water pressure pushing the berg,” he says. “The vessel will hold station and the force of the water will push the berg. It’s one of the most effective means of managing difficult-to-tow icebergs.”

The prop wash method is not used as much as it once was. It consists of backing up close to the offending iceberg and gunning the engines so the boat’s prop wash impinges on the berg and drives it off course. Strong says it’s a very tedious job. “You just back up near it and then it’s back and forth, back and forth.”

Whatever the method used, captains are intimately familiar with them all. “It’s part of a supply vessel captain’s requirements,” says Strong. “Like towing rigs, anchors, all things required of captains of offshore supply vessels. Once you move into the iceberg management component it kind of fits the whole picture.”

The captains are busier with icebergs some years than others. Strong shows me a chart of the past 15 years of iceberg sightings and how many of those were threats that needed managing. “The mean or average is 800 sighted over this 15-year span,” he says, pointing to the spot. Recent years are more telling–numbers vary considerably from season to season. The graph shows they had to manage 70 in 2000, none in 2001, 37 in 2002 and 106 in 2003. “So you can see the volume we have,” he says. “On average, if we run into 800 or 1,000 (sighted) bergs we’re in the 30 to 40 zone that need management. Once we get up to over 1,200 or 1,300 bergs we’re getting up towards a 100 that need managing.”

By late June the number that needed managing has dropped. Despite the picturesque approach to St. John’s airport and the tourists that flock to see them, the number of sightings is already down considerably. Later in the year they’ll be gone completely.

Growlers And Rollers

Icebergs are identified by size and nicknames:

· Growlers: an iceberg the size of a grand piano

· Bergy Bits: as big as a garage

· Small Berg: as big as a mansion

· Medium Berg: as big as a large ship

· Large Berg: as big as a stadium

· Very Large Berg: as tall as a 23-storey building–and taller.

The largest iceberg ever recorded in the Northern Hemisphere was 13 kilometres by six kilometres and weighed over 9 billion tonnes. It was sighted in 1882.

Advertisement